An auxiliary battery system complements modern vehicles by providing sustained power for non-critical functions like radios, GPS, and lighting, especially when the engine is off or idling. It's designed to recharge independently through the vehicle's alternator or a dedicated charging system, ensuring it's always ready for immediate use without depleting the main starter battery's charge. Proper maintenance of the auxiliary battery, including regular checks on its charge levels, connections, voltage regulators, and charging circuits, is crucial for efficient vehicle electrical operation and to prolong both batteries' lifespans. Auxiliary batteries are also critical in various sectors, from automotive to renewable energy systems, where they must withstand environmental challenges such as extreme temperatures, which can degrade their performance and require proper insulation and maintenance. Regular upkeep, including terminal cleaning, secure connections, and storage in a cool, dry place, helps prevent issues like corrosion, overcharging, and sulfation, ensuring the battery's longevity and optimal operation. For lead-acid auxiliary batteries, monitoring electrolyte levels, checking vents for proper function, and adhering to manufacturer guidelines are essential for maintaining their performance and safety. Regular maintenance and following recommended practices are key to preserving your auxiliary battery's lifespan and ensuring it operates at peak efficiency.

When confronted with an unexpected vehicle breakdown, often the culprit is an auxiliary battery that has failed. This article delves into the pivotal role of auxiliary batteries within automotive systems and pinpoints the common causes behind their malfunctions. From inadequate charging processes to the effects of extreme temperatures, age-related degradation, and corrosion undermining connections, we explore the myriad factors that can compromise an auxiliary battery’s performance. Understanding these issues is crucial for maintaining vehicle reliability. By examining each element in detail, we aim to equip readers with the knowledge necessary to prevent auxiliary battery failures and extend their operational lifespan.

- Understanding the Role of an Auxiliary Battery in Vehicle Systems

- Common Causes of Auxiliary Battery Failures

- Inadequate Charging as a Catalyst for Auxiliary Battery Malfunction

- The Impact of Extreme Temperatures on Auxiliary Battery Performance

- Age and Degradation: Natural Enemies of Auxiliary Batteries

- Corrosion and Connection Issues in Auxiliary Battery Systems

- Preventative Measures and Maintenance Tips to Extend Auxiliary Battery Life

Understanding the Role of an Auxiliary Battery in Vehicle Systems

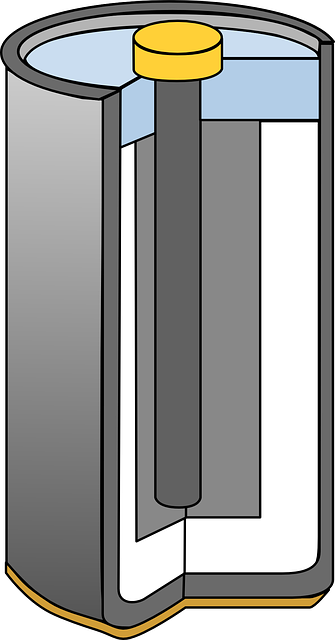

An auxiliary battery plays a pivotal role in modern vehicle systems, complementing the main starter battery to cater to ancillary functions that are less critical for immediate engine start-up but indispensable for the comfort and functionality of the vehicle while running. Unlike the primary battery, which is solely responsible for cranking the engine, the auxiliary battery is designed to handle a continuous power draw without compromising the main battery’s charge. It powers accessories such as radio systems, GPS units, and lighting when the engine is off or idling. This dual-battery setup extends the vehicle’s capabilities by allowing users to run electronic devices indefinitely without risking a flat starter battery. The auxiliary battery is typically charged through the main alternator or a dedicated charging system, ensuring it is always ready for use. Understanding the nuances of how an auxiliary battery functions and its role within the vehicle’s electrical ecosystem is crucial for maintaining optimal performance and longevity of both batteries and the vehicle’s electronic systems. Regular maintenance, including checking battery charge levels and connections, inspecting voltage regulators, and ensuring proper charging circuits, is essential to prevent auxiliary battery failures, which can leave drivers stranded or without essential vehicle functions.

Common Causes of Auxiliary Battery Failures

Auxiliary batteries are critical components in many applications, from powering off-grid renewable energy systems to providing backup power for vehicles and emergency equipment. Unfortunately, auxiliary battery failures can occur due to a variety of common causes that can be mitigated with proper care and understanding. One prevalent cause of failure is sulfation, which occurs when sulfur crystals form on the battery’s lead plates, reducing the battery’s ability to hold a charge. This can happen over time, especially if the battery is not fully charged regularly or is left in a discharged state for extended periods. Another significant factor contributing to auxiliary battery failures is extreme temperatures. Both high heat and cold can degrade battery performance and lifespan. High temperatures can cause electrolyte evaporation and lead to water loss, while low temperatures can thicken the electrolyte solution, impeding the chemical reactions necessary for energy storage and retrieval. Additionally, the charging practices play a crucial role; overcharging or undercharging can cause irreversible damage to the battery’s cells, leading to reduced capacity and eventual failure. It is essential to use a compatible charger with appropriate settings to prevent such issues. Regular maintenance, including checking electrolyte levels, cleaning terminals, and ensuring proper ventilation, can significantly reduce the likelihood of auxiliary battery failures due to these common causes. Understanding these factors is key to prolonging the life and reliability of auxiliary batteries in any application.

Inadequate Charging as a Catalyst for Auxiliary Battery Malfunction

Inadequate charging is a significant factor contributing to auxiliary battery malfunctions, often leading to unexpected power loss in critical systems. These batteries, which provide essential support for vehicle electrical loads or back-up power in various applications, rely on consistent and proper charging protocols to maintain optimal performance. When subjected to suboptimal charging conditions, such as insufficient voltage, current, or erratic charging patterns, auxiliary batteries can experience degraded capacity and reduced lifespan. This is particularly true for lead-acid batteries, which require a specific charging regime to prevent sulfation, a process where sulfuric acid doesn’t recombine with lead dioxide on the plates, leading to decreased efficiency over time. To mitigate such issues, it is crucial to adhere to the manufacturer’s recommended charging parameters and schedules. Additionally, employing battery management systems can monitor the state of charge and health, providing alerts for necessary maintenance or recharging actions before full depletion occurs, thus preventing premature battery failure and ensuring reliability in its critical support roles. Regular monitoring and proactive maintenance are key to prolonging the life of auxiliary batteries and avoiding the inconvenience and potential safety hazards associated with their unexpected failure.

The Impact of Extreme Temperatures on Auxiliary Battery Performance

Extreme temperatures can significantly impact the performance and lifespan of an auxiliary battery, influencing its ability to hold a charge and start an engine reliably. In hot climates, excess heat can accelerate the chemical reactions within the battery, leading to increased internal resistance and reduced capacity over time. This degradation is often exacerbated by poor ventilation or inadequate cooling systems that are commonly found in vehicles operating under such conditions. Conversely, in cold environments, the viscosity of the electrolyte solution becomes thicker, which slows down the reactions necessary for the battery to function optimally. This can result in a reduced ability to accept a charge and a lower voltage output, making it harder for the battery to start a vehicle on cold mornings. The performance drop at low temperatures can be further compounded by factors such as a reduction in the battery’s internal pressure and a decrease in its overall energy density. To mitigate these effects, it is crucial to insulate auxiliary batteries properly and to perform regular maintenance checks to ensure they remain functional across a wide range of temperatures, thereby enhancing their longevity and reliability.

Age and Degradation: Natural Enemies of Auxiliary Batteries

Auxiliary batteries, crucial components in a variety of applications from automotive to renewable energy systems, are subject to natural enemies such as age and degradation. Over time, these batteries inevitably experience a decline in performance due to the chemical processes at play within their cells. As the auxiliary battery ages, its ability to hold a charge diminishes, which is primarily attributed to the sulfation process. This occurs when sulfuric acid in the electrolyte reacts with lead in the positive plates to form lead sulfate, a less reactive compound that coats the plates and reduces the surface area available for energy storage. Additionally, the internal resistance within the battery increases, leading to higher voltage under load and reduced efficiency.

Degradation can also be accelerated by environmental factors such as extreme temperatures, which can cause the electrolyte to either evaporate or separate from the active materials at an accelerated rate. Further, self-discharge, where the battery loses charge over time even when not in use, is a natural process that all auxiliary batteries must contend with. This loss of charge is due to the constant chemical reactions occurring within the battery, which inevitably lead to a decrease in capacity and voltage output. To mitigate these effects, regular maintenance, proper charging practices, and the use of battery conditioners are recommended to extend the lifespan of auxiliary batteries and maintain their optimal performance.

Corrosion and Connection Issues in Auxiliary Battery Systems

When dealing with auxiliary battery systems, corrosion and connection issues are prevalent causes of failure that can significantly impact the reliability and efficiency of the power source. Corrosion on terminals and connectors is a pervasive concern in auxiliary battery management. It often occurs due to environmental factors like humidity, temperature variations, and the presence of conductive materials such as salt or dirt. This corrosion forms an oxide layer on the battery terminals, which can impede the electrical connection, leading to poor conductivity and inconsistent power delivery. Consequently, the battery may struggle to hold a charge, or worse, fail to operate entirely. Regular inspection and maintenance, including cleaning and applying protective coatings, are essential to mitigate corrosion risks.

In parallel with corrosion, connection issues in auxiliary battery systems can arise from poor-quality hardware, loose connections, or incorrect installation practices. These issues manifest as intermittent power supply or complete loss of electrical contact, which can be particularly problematic in applications where consistent power is critical. The integrity of the connections should never be underestimated; a seemingly minor issue can lead to significant system malfunctions. To prevent such occurrences, it is imperative to use high-quality battery terminals and connectors, ensure secure tightening without overtightening, and adhere to proper installation guidelines. Regular checks and proactive maintenance are key to maintaining the health of your auxiliary battery system and ensuring its longevity and performance.

Preventative Measures and Maintenance Tips to Extend Auxiliary Battery Life

Regular maintenance and proactive measures are pivotal in extending the life of an auxiliary battery. To begin with, ensure that the battery is installed correctly, as incorrect installation can lead to improper charging and reduced battery performance. Monitoring the charge and discharge cycles is crucial; avoid allowing the battery to be completely drained or overcharged, as this can degrade its capacity significantly. Keep the terminals clean and free from corrosion, which can disrupt the electrical connections and affect the battery’s efficiency.

Furthermore, storing the auxiliary battery in a cool, dry place away from direct sunlight will prevent excessive heat or cold from damaging the internal components. Regularly check the electrolyte levels if you have a traditional lead-acid battery; maintaining proper electrolyte concentration is essential for optimal battery function. For maintenance-free batteries, check the condition of the vents to ensure they are not clogged and that the battery casing remains intact, as these are designed to manage pressure and prevent leakage or explosion. Regular inspections, coupled with adherence to the manufacturer’s guidelines for charging rates and usage patterns, can significantly enhance the lifespan of your auxiliary battery.

In conclusion, auxiliary batteries play a pivotal role in the functionality of modern vehicle systems. Understanding common causes such as inadequate charging, extreme temperature effects, natural age and degradation, corrosion, and poor connections is crucial for the maintenance and longevity of these batteries. Regular inspection, proper charging practices, cleaning corroded terminals, and implementing preventative measures can significantly extend the life of an auxiliary battery. By adhering to maintenance tips provided in this article, vehicle owners can minimize failures and ensure their auxiliary batteries perform reliably when needed most. Proactive care is key to safeguarding against the unforeseen consequences of auxiliary battery malfunctions on the road.